Inside the World of Professional Model Making

Model making might sound like something you’d find in a school design project or hobbyist’s garage – but in reality, professional model makers play a critical role in industries ranging from architecture and engineering to film, exhibitions and product design.

At JH May, we help businesses visualise and test their ideas, in this article we’ll lift the lid on the model making process, explain how professional model makers work, and explore the wide variety of models used across different sectors.

What Is a Model Maker?

A model maker is a skilled craftsperson who creates three-dimensional representations of objects, products, buildings or concepts. These models can be static or functional, scaled-down or full-size, and are typically used for design validation, communication, marketing or educational purposes.

Professional model makers work with a combination of hand tools, digital manufacturing techniques and specialist software to produce high-precision, high-impact models.

What Types of Models Do Professionals Make?

Model making isn’t a one-size-fits-all service. At JH May, our expert model makers work across industries and project types – each with their own challenges, technical requirements, and creative goals.

Here’s a closer look at the types of professional models we produce:

Architectural Models

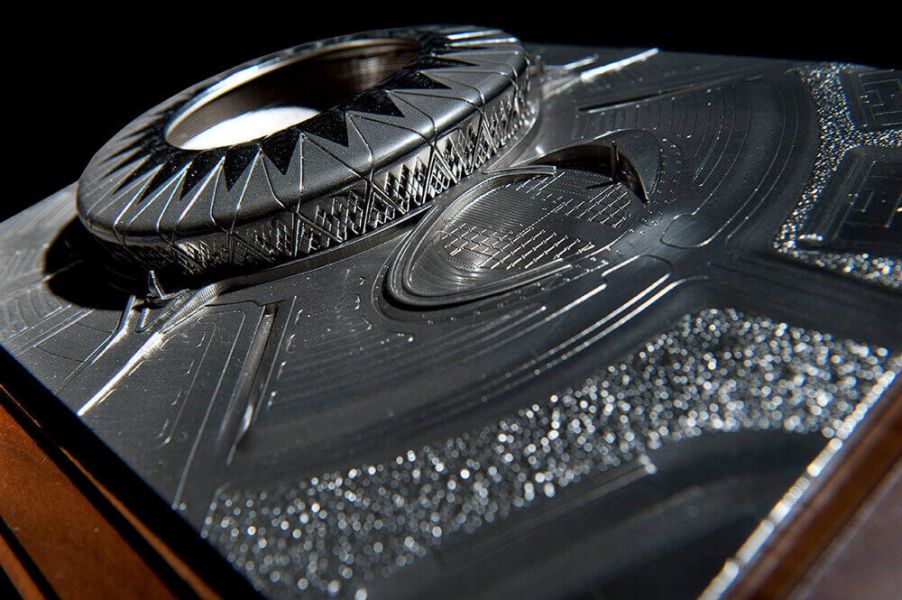

Architectural models are essential tools for communicating design intent. Whether it’s a residential development, commercial building, or public space, a physical 3D model helps planners, clients and stakeholders visualise the finished project.

Our architectural model makers use precision techniques and materials to replicate everything from building facades to complex landscaping. These models are often used in planning meetings, public consultations, and investor pitches to generate excitement and clarity.

Popular with: Architects, property developers, town planners, and local authorities.

Product Models

Before a product goes to market, a physical model can be an invaluable asset. We create highly detailed product models for presentations, photography, usability testing, and exhibitions. These are often made to look and feel exactly like the final item, even before full production begins.

Using CAD, CNC machining and finishing expertise, our model makers replicate textures, colours and branding with precision. Whether you’re pitching to investors or preparing a product launch, a model can help you stand out.

Popular with: Product designers, engineers, marketing teams, and entrepreneurs.

Mechanical Models

Mechanical models demonstrate how a mechanism works in real life—ideal for showcasing engineering concepts, simplifying complex machinery, or teaching how a system functions.

Mechanical models demonstrate how a mechanism works in real life—ideal for showcasing engineering concepts, simplifying complex machinery, or teaching how a system functions.

Our team can build interactive or moving models that simulate motion, gears, hydraulics, or electrical processes. These are often used in education, engineering demos, or exhibitions to help audiences grasp technical processes more easily.

Popular with: Engineering firms, training providers, museums, and R&D teams.

Display & Exhibition Models

Built to grab attention and spark conversation, display and exhibition models are often large-scale, visually striking, and designed for high footfall environments. From point-of-sale replicas to dramatic centrepieces at trade shows, we create models that blend artistry with impact.

Our model makers craft these pieces with durability and transportability in mind—ensuring they can handle busy event environments without compromising on aesthetics.

Popular with: Event organisers, retailers, museums, and marketing agencies.

Bespoke Models

Not every project fits a category and that’s where our bespoke model making service comes in. We specialise in one-off commissions and unusual requests, working closely with clients to create something truly unique.

Think museum exhibits, film props, branded installations, or intricate replicas of heritage objects. If you can imagine it, chances are we can build it.

Popular with: Creative agencies, curators, film and TV production companies, and brand teams.

Why Businesses Use Model Makers

While 3D renders are useful, there’s something uniquely powerful about holding or viewing a tangible object. A well-made model helps:

- Visualise a design before production or build

- Spot flaws or improvements early in the process

- Create a memorable impact in marketing or pitches

- Engage audiences in exhibitions or educational settings

It’s no surprise that industries from aerospace to advertising rely on professional model makers to bring their ideas to life.

What Skills Do Model Makers Have?

Professional model makers are multi-skilled specialists who blend creativity with technical expertise. Far from being just craftspeople, they often act as designers, engineers, problem-solvers and finishers all rolled into one. The job demands precision, patience, and the ability to bring abstract ideas into tangible, physical form.

Professional model makers are multi-skilled specialists who blend creativity with technical expertise. Far from being just craftspeople, they often act as designers, engineers, problem-solvers and finishers all rolled into one. The job demands precision, patience, and the ability to bring abstract ideas into tangible, physical form.

At JH May, our model makers draw on a broad skill set to deliver models that are not only accurate but also visually impressive and built to last.

Here’s a closer look at the key skills involved:

1. CAD Design and Digital Planning

Modern model making starts with detailed planning. Our team uses advanced CAD software, such as SolidWorks and Rhino to develop accurate 3D designs and technical drawings. This allows us to visualise, adjust and approve each component before anything is physically made.

CAD design ensures precision, helps reduce waste, and gives clients a clear idea of what the final model will look like.

Essential for: Engineering models, product prototypes, and architectural builds.

2. CNC Machining and 3D Printing

Fabrication is at the heart of what we do. Our model makers are trained in using CNC (Computer Numerical Control) machines to cut and mill parts with micron-level accuracy. For more complex or curved components, we also use industrial 3D printing technologies.

This combination of subtractive and additive manufacturing ensures flexibility, speed, and exceptional detail, especially for bespoke or intricate projects.

Used across: Mechanical models, scale models, and product displays.

3. Hand Finishing and Surface Detailing

Even the most precisely manufactured model needs the right finishing touches. Our model makers are skilled in a range of surface techniques – from sanding, priming and painting, to airbrushing, polishing, and applying textures or decals.

The finishing stage brings the model to life, making it visually realistic and presentation-ready.

Vital for: Architectural displays, exhibition models, and high-end prototypes.

4. Creative Problem Solving

No two model making projects are exactly alike. Whether it’s working with unusual materials, replicating a complex mechanism, or adapting to last-minute design changes, our model makers are expert problem-solvers.

They think creatively under pressure, find practical workarounds, and ensure that technical challenges never derail a deadline.

Crucial for: Bespoke models, interactive features, and tight-turnaround jobs.

5. Team Collaboration and Communication

Model making rarely happens in isolation. Our model makers collaborate closely with clients, designers, engineers, and marketers throughout the process – from initial concept meetings to final handover.

Clear communication ensures that expectations are aligned, feedback is implemented quickly, and the final result meets both technical requirements and creative goals.

Important for: Large-scale projects, corporate briefs, and cross-discipline teams.

A Multi-Disciplinary Team Under One Roof

At JH May, we pride ourselves on housing a full-service team of model makers, engineers, and 3D designers all in one location. This allows us to move seamlessly from concept to completion, maintain tight quality control, and deliver consistently outstanding results.

When you work with JH May, you’re not just hiring model makers – you’re gaining access to decades of experience, technical expertise, and a shared passion for excellence in every project we take on.

The Model Making Process: Step by Step

At JH May, we believe great results come from a clear, collaborative process. Whether we’re building a one-off product prototype or a large-scale architectural model, our team of expert model makers follows a refined workflow to ensure accuracy, consistency and client satisfaction.

Here’s how a typical project unfolds:

1. Initial Brief & Consultation

Every project begins with a conversation. We take time to understand your objectives, target audience, budget, timescale and any technical or creative requirements.

We’ll ask the right questions to clarify:

- What is the model’s purpose? (e.g. display, testing, demonstration)

- Who will use or view it?

- What scale, materials or finishes do you have in mind?

- Are there any working parts or interactive features?

Our goal is to gather everything we need to quote accurately, avoid surprises, and deliver a model that exceeds expectations.

2. CAD Design & Digital Planning

Once the brief is agreed, we move into the design phase. Our model makers use professional CAD software such as SolidWorks or Rhino 3D to digitally visualise the entire model before fabrication begins.

This stage allows for:

- Detailed dimensional planning

- Early testing of components and fit

- Realistic renders for client approval

- Design tweaks before materials are committed

It’s a vital step for ensuring accuracy and efficiency, especially for complex or large-scale builds.

3. Fabrication of Components

With the design finalised, we begin manufacturing the model’s components. Depending on the size, materials and level of detail required, we use:

- CNC machining for precision-cutting parts from wood, metal or plastic

- 3D printing for intricate shapes or organic forms

- Handcrafting for bespoke detailing or sculptural elements

Because all fabrication takes place in-house at our Essex workshop, we maintain full control over quality and turnaround times.

4. Assembly & Finishing

Once all parts are fabricated, our skilled model makers assemble the model with care and precision. This stage includes:

- Structural assembly and bonding

- Painting, airbrushing and surface detailing

- Application of textures, decals or branding

- Installation of lighting or interactive features (if applicable)

This is where the model truly comes to life, transforming from a set of parts into a fully finished, visually impressive piece.

5. Quality Checks & Delivery

Before the model leaves our workshop, it undergoes a thorough inspection. We test for durability, finish quality, accuracy to the brief, and functionality (if applicable).

Only when we’re fully satisfied does the model get carefully packed and prepared for delivery or installation. We offer secure packaging, transportation support and advice on long-term storage or handling where needed.

A Proven Process, Trusted by Professionals

Our model making process has been refined over decades of delivering projects for architects, engineers, brands and creatives across the UK and beyond. Whether it’s your first model or your fiftieth, we’ll guide you through every step with clarity, expertise and professionalism.

Looking to get started on a model project? Contact Us today to discuss your brief.

Choosing the Right Model Maker

Not all model makers are the same. Look for:

- Proven experience across industries

- In-house technology and skilled staff

- Strong communication and project management

- Attention to detail and commitment to deadlines

JH May has been trusted by UK businesses for over a century, delivering high-quality models that stand out.

Model makers do far more than just build pretty replicas. They help businesses test ideas, win pitches, engage audiences and tell powerful stories.

If you’re looking for professional model makers in the UK, we’d love to hear about your project. With decades of experience and some of the best facilities in the country, JH May is ready to bring your ideas to life.

Need a professional model made?

Call 01277 365500 to speak to our team today.