We have over 50 years experience in reverse engineering functional and non-functional parts, assemblies and mechanisms. More recently we have embraced 3D laser scanning, rapid prototyping, cnc machining and rapid metal casting technologies.

We employ 3D CAD designers, operating our Solidworks CAD software enabling us to draw any component part or entire machine/assembly into an up to date format. (IGES, STEP, STL, DXF, DWG, OBJ, SAT, SLDPT, IGS, STP)

In this way we can utilise the latest 3D CNC Machining, rapid prototype (SLA, SLS, Voxeljet), rapid metal casting, vacuum casting and RIM moulding technologies to reverse engineer virtually anything.

We can get the same advantage by employing 3D laser scanning technology. Pieces up to 2 metres in length can be 3D laser scanned. We can then convert the 3D surface data captured into a format that can be read by our rapid prototype layer technology machines and CNC machining/CNC turning centres (DXF, DWG, IGES, STEP, STL, OBJ, SLDPT, IGS, STP, SAT).

The combination of this 3D technology and our extensive manufacturing and mechanical engineering experience means that our reverse engineering service is second to none.

J H May engineers have been involved with countless major engineering and prototyping projects for many of the worlds major companies. It is this experience gained over many years which ensures our in-depth understanding of all mechanical engineering disciplines. This knowledge combined with our extensive CNC machining, 3D CAD design, rapid prototyping and laser scan facilities is a fantastically powerful tool for reverse engineering in all circumstances.

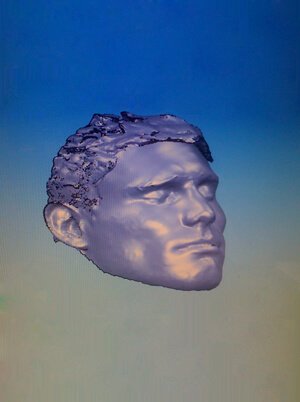

Today’s high tech approach to reverse engineering is not restricted to mechanical and engineering based projects. Our clients who specialise in Art sculpture and physical 3D models have taken advantage of our reverse engineering technology. With a physical piece we can 3D laser scan or draw straight into 3D CAD via Solidworks. Once the 3D data capture is complete the piece can be re-produced via CNC machining or rapid prototyping at any scale in virtually any material.

We would love the opportunity to review your reverse engineering requirements.

Please take a look at several case studies as follows which demonstrate the use of laser scanning, rapid prototyping , 3D CAD design and CNC machining.