The art of reverse engineering is invaluable for many different projects. Reverse engineering is the process of taking something apart to understand how it works and develop another product or part which can either work with the original product, enhance the original part or improve its functionality.

Reverse engineering really can help to solve all sorts of manufacturing problems and can be useful for the latest modern technology and in the manufacture of parts which have become obsolete.

Technology is moving at a rapid pace but there are many people who harp back to the old days – steam engines, classic motor cars, traditional railway carriages. The problem with some of these engines and other mechanical objects is very often the maintenance – replacement parts which haven’t been manufactured for many years can be incredibly difficult to come by.

This is one of the areas which reverse engineering can be used in – taking apart an original product to see the components within and manufacturing a new part which can be used in connection with the original.

Other reverse engineering projects involve much more modern equipment and technological problems.Even the latest cutting edge, state of the art machinery can have flaws in design or manufacture which can cause severe disruption to production lines and the manufacturing industry. Finding a company which is experienced in reverse engineering can help to solve these potential problems quickly and efficiently before too much production time and hence profit is lost.

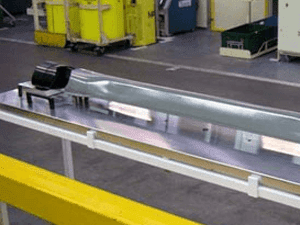

Our experienced team are experts at reverse engineering and producing components to combat problems and find solutions quickly and easily. The manufacture of prototype working or exhibition models can provide the confidence that all products will work efficiently and effectively when they eventually go into production.

Where on earth would the world be without reverse engineering?