We were asked by an engineering team from a large London university to manufacture parts for an upcoming project – a prototype Eco-car, taking part in a marathon challenge of driving almost 18,000 metres on a single litre of fuel.

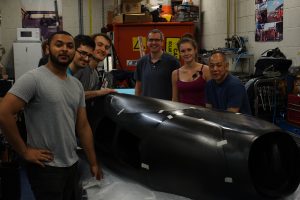

The car, named The Hydrone, is a lightweight tubular vehicle with enough space for one person, and the body is assembled mainly from carbon fibre and other lightweight materials. The team hoped that this would give their prototype the edge on the track, even though teams from all over the globe were in attendance and also using high-tech materials to race for the same prize.

Our part of the project, manufacturing windscreens and windows for the prototype Eco-vehicle, meant we had to combine multiple aspects of our business. We had to create a finished product that was perfect, precise and with a very fast turnaround; it was being bolted together just the day after we’d finished manufacturing. We had to create and transport the parts rapidly, with no room for error.

More about the process

ore about the process

To create the windows and windscreens, which would have been manufactured from glass in a traditional car, we used vacuum-formed plastic; the shape of the windows were specified by engineers from the university, as they had to be incredibly aerodynamic to give the vehicle the least drag possible. This was achieved by creating tooling, CNC machined from blocks of ureol model board, which was a precise copy of the CAD file we received from the university’s engineers; these had been designed specifically to give the minimum wind resistance when the car was in motion.

Once the tooling had been machined on our CNC machining centre, we began the vacuum forming process; this involves warming a sheet of plastic and using pressurised air to pull it over the tooling, which leaves a well-defined imprint of the original piece in clear plastic. Once this is cut out of the sheet, and the edges are carefully sanded down to make it safer to handle, the finished part is ready to be installed on the prototype vehicle. The advantage of this style of manufacturing is being able to produce a well-defined custom shape from transparent lightweight material, and it made it possible for us to manufacture spares for any pit-stop repairs that may be necessary!

We always enjoy working on projects where we can see our finished parts being displayed proudly, and seeing the pictures of the finished Hydrone left us all in awe. We wish the team the best of luck in fine-tuning their impressive Eco-car for all future races.

or more information on the European leg of the Shell Eco-Marathon, visit

https://www.shell.com/what-we-do/technology-and-innovation.html