Some products require reverse engineering due to CAD data not being available. This means an existing component of the part to be manufactured has to be 3D laser scanned first, in order to create 3D CAD files.

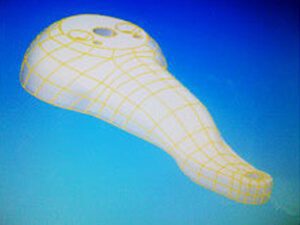

Once the 3D CAD file has been created we can utilise rapid prototyping techniques to make models which can be checked to validate the laser scan data. Following validation the same data is used to create the part in the production material on either a 3 axis or 5 axis CNC milling machine. We are currently using this process to produce stock of the Dead Man’s Handle. Used on trains to ensure the driver’s grip doesn’t loosen on the handle, the train will automatically stop in the event of this happening in case of an incident involving the driver.

Stock of these handles was made in the 70’s and is now all in use, so once we had scanned an existing handle we could then create the files from which we directly CNC machine the new parts from solid aluminium blocks.

As this is one part of a mechanism on the train, we have to guarantee the handles will interface with the remaining parts once the handles are completed. Without drawings and customer specifications, checking dimensions at all stages throughout production is crucial. Once completed, the handles will be hard anodized, leaving them with a protective surface finish to withstand years of continuous use.