When designing models for companies around the globe we often have to work to a fast delivery date, set to meet an international marketing campaign, a product launch, a shop opening or museum event. When this is the case, there’s no chance of a deadline extension and we have to pull out all the stops. Here are some of the things we implement when we have a project with a short delivery time:

Design Well

Having a well-designed CAD for any project means that when it comes time to manufacture, we’re all working together to achieve a high-quality product. Our design engineers can take your concept and turn it into a perfectly realised 3D rendering, with input from you to make sure we’re both seeing the same finished product. Engineers, artists and our management team can then view the CAD and anticipate any upcoming problems; this way, models only have to be made once. Byran, one of our design engineers, knows that CAD can help all aspects of manufacture: “CAD data is used by everyone in the workshop. We constantly check measurements and the way complex components join together by looking at a rendering of the finished image. As everyone is working to the same design, we already know the different components of the model will come together perfectly.”

Utilise Advanced Manufacturing Techniques

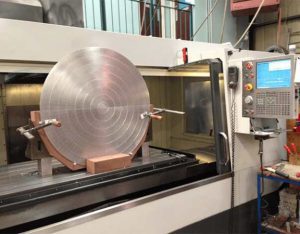

Taking full advantage of modern manufacturing techniques allows us to create outstanding models in a fraction of the time it’d take to make them by hand. We use 3 axis and 5 axis CNC Milling Machines, which allows our engineers to secure some wood or metal to a bench, go home, come back the next morning and there’s an ornate sculpture sitting in its place. Along with our sister company Thompson Precision, we have 22 of them; all have different uses and work best in different situations, and some of them are remote controlled and viewable via webcam, so you don’t even need to be in the same room while they’re whirring away.

As well as the CNC capacity, which can manufacture models from a variety of materials including metals, wood, plastic and model board, we also have over a decade of experience working with Rapid Prototyping. Rapid Prototyping, which includes 3D printing as well as other techniques, is the fast manufacture of complex designs using a combination of CAD and some variation of layered materials to form intricate geometric structures. Designing and producing complex 3D printed models allows us to shorten the time frame of many different processes, with 3D printing often taking much less time than traditional manufacture. Once the model has been 3D printed, it then gets sanded down and hand finished by our expert model makers, showing how traditional methods of manufacture and new technology work together to achieve excellence, even within a tight deadline.

Work Hard

There really is no substitute. Our team of model makers and engineers can utilise their combined experience to manufacture items quickly and efficiently. Making your product our sole focus means our team designing, creating and perfecting your project around the clock until it is complete. That commitment to completing a project is often the catalyst needed to produce excellent projects when a deadline is looming ominously, and has meant we’ve achieved success when our clients had been let down by another supplier, or when other model makers have been unable to help.

So if you need the services of a Model Making company who strive to produce high quality products even when time is tight, contact JH May today to see what we can do for your next project; whether it’s a shop display, large-scale artwork or a prototype of a new product, we’ll complete your project to the highest standard even with a tight deadline.